Do You Need Paint Correction Before Ceramic Coating? Benefits and Preparation Tips

Thinking about getting a ceramic coating for your car? You might assume you can just apply it and call it a day, but there's an important step many people overlook: paint correction. Without properly addressing surface imperfections and oxidation first, that high-tech coating won't adhere properly or deliver optimal results. It's like putting a clear jacket over a wrinkled shirt; you'll still see those imperfections underneath. In this article, we'll break down why paint correction matters so much before ceramic coating and share tips to help you achieve the best results possible.

Yes, paint correction is highly recommended before applying a ceramic coating because it removes existing imperfections such as haze and oxidation, ensuring a smooth, flawless surface for the coating to bond properly. This step not only enhances the overall appearance but also maximizes the durability and effectiveness of the ceramic coating in protecting your vehicle's paint.

Key Takeaways

- Paint correction extends ceramic coating lifespan by up to 50% through proper surface preparation and bonding.

- Corrected surfaces deliver superior hydrophobic performance, making water and contaminants bead off effortlessly.

- Vehicles with paint correction and ceramic coating sell for up to 15% more than those with visible paint defects.

- Multi-stage correction process removes haze and oxidation that would otherwise be sealed under the coating.

- Professional preparation using pH-neutral wash, clay bar, correction, and IPA wipe-down ensures maximum coating effectiveness.

Why Paint Correction Matters Before Ceramic Coating

When we look closely at vehicle paint, we often discover it's not as flawless as we'd like. Surface haze from improper washing, oxidation caused by UV exposure, and other imperfections accumulate over time.

These defects interrupt the smooth surface needed for ceramic coatings to bond effectively. Applying a ceramic coating over flawed paint is like laying wallpaper over cracked drywall: the imperfections remain visible and can worsen under certain lighting conditions.

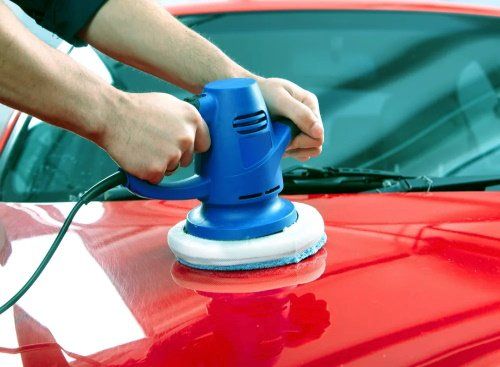

Paint correction involves a meticulous, multi-stage process where trained technicians use specialized compounds and polishes combined with machine polishers to remove these defects carefully. The goal is to strip away damaged clear coat layers until only pristine paint remains. This doesn't mean aggressively sanding down the paint but rather controlling the depth of correction so that clarity and gloss are restored without compromising the vehicle's finish integrity.

What Happens When You Skip Paint Correction?

Without proper correction, ceramic coatings cannot seal imperfections; they simply lock them in place. This reduces the coating's ability to reflect light beautifully, making your vehicle appear dull rather than dazzling. Moreover, uncorrected surfaces allow contaminants to adhere more easily, shortening the lifespan of both your paint and protective layer.

Common Paint Issues Correction Addresses

Our corrective process targets several paint problems that degrade appearance and protection:

Surface haze caused by improper washing and drying techniques

- Light surface imperfections from environmental contact

- Oxidation which dulls paint and makes colors fade

- Water spots etched into the clear coat by mineral deposits

- Cloudiness due to age and exposure

- Surface contaminants like bird droppings or tree sap stains

When these defects go untreated, they create a rough microscopic surface that diminishes paint gloss and promotes faster wear. Through careful compounding and polishing, we restore smoothness, allowing ceramic coatings to achieve their full hydrophobic and self-cleaning potential.

How Paint Correction Fixes Surface Imperfections and Haze

Not every imperfection is the same. Recognizing this difference helps us choose the right restoration method. Some issues only graze the outermost clear coat, typically surface haze from washing with improper techniques. These are usually shallow, but their presence dulls the shine and texture.

More substantial imperfections may require deeper attention but can still be addressed through correction. Understanding where an imperfection sits determines how we work on it.

Correction Techniques by Severity Level

- Light Surface Defects: We start with mild polishing compounds designed to gently smooth out imperfections without excessively thinning your clear coat. This phase restores initial gloss, making your car appear almost like new.

- Moderate Surface Imperfections: These require medium-cut polishes that are slightly more abrasive but still controlled carefully to avoid damaging underlying paint. It often takes two or three passes with a dual-action polisher at precise speeds to refinish these areas effectively.

- Deeper Clear Coat Issues: These demand a multi-stage correction plan. We begin using heavier cutting compounds to level out irregularities. Once most defects are smoothed away, we move to finer polishes that refine the surface and remove haze or micro-marring caused earlier in the process.

Professional Equipment and Techniques

Using the right equipment is vital for proper treatment. A high-quality dual-action polisher allows us to apply abrasive agents evenly while reducing risks of additional damage such as holograms or burning through your paint layer. At our facility, we rely on industry-leading machines for precision control and power balance.

These advanced tools let our technicians adjust speed and pressure dynamically. Slower rotations paired with lighter pressure work for delicate surfaces, while faster speeds tackle stubborn defects, ensuring every inch receives careful, professional treatment.

Restoring and Enhancing the Clear Coat

The clear coat is more than just a shiny finish; it's the transparent barrier guarding your car against UV rays, oxidation, environmental contaminants, and light surface damage. Think of it as the last line of defense between your paint and the world outside. When this layer is compromised through fading or surface haze, it dulls your vehicle's appearance and weakens how well any protective coating can adhere.

The Clear Coat Restoration Process

Restoring the clear coat is the central step before applying ceramic coating. We describe this process as polishing a glass window that has dulled over time. Paint correction uses specialized machines and compounds to gently remove surface imperfections and haze that accumulate from everyday use.

It's a meticulous task requiring skill and experience because removing too much material damages the clear coat, while too little leaves defects behind.

One product we frequently integrate is a specialized sealant. This type of sealant enhances gloss while preparing the surface to receive ceramic coating. It creates a smooth, slick finish that improves chemical bonding between your vehicle's surface and the protective layer applied afterward.

Benefits of Proper Clear Coat Preparation

Once the clear coat is fully restored and primed, ceramic coating can perform optimally. A well-prepped clear coat delivers:

- Improved Bonding: The coating forms a stronger chemical bond on a smooth surface free from contaminants.

- Deeper Shine: Proper leveling enhances light reflection, giving your vehicle that deep, mirror-like gloss.

- Extended Durability: The coating performs longer and resists wear better when bonded to a clean, polished surface.

- Enhanced Protection: Ceramic coatings repel water, dirt, road salts, and UV rays more effectively.

Essential Preparation Steps Before Ceramic Coating

Before applying any ceramic coating, we must complete a thorough preparation process that lays the foundation for a durable and beautiful finish. This creates an immaculate surface free of contaminants, oils, or imperfections that could compromise coating effectiveness.

Step 1: Thorough pH-Neutral Washing

The first crucial step is washing using pH-neutral shampoos. Unlike harsh detergents that strip away protective layers or leave residue, pH-neutral shampoos gently lift dirt, road grime, and pollutants without damaging paint. This cleansing phase ensures the surface is fully accessible for deeper decontamination.

Step 2: Clay Bar Decontamination

Washing alone isn't enough. Even after rinsing, invisible particles like tree sap, industrial fallout, or brake dust cling stubbornly to your car's paint. The clay bar acts like an eraser for these microscopic impurities embedded beneath the clear coat's surface. Running it methodically over each panel removes embedded debris, smoothing out roughness you might not see but can definitely feel.

Step 3: Multi-Stage Paint Correction

With contaminants removed, we address existing paint defects through paint correction. Visible surface haze and oxidation spots aren't just unsightly; they create gaps and uneven spots where ceramic coatings won't adhere optimally.

By employing multi-stage polishing techniques tailored to your paint's condition, we restore clarity and gloss, creating an ideal canvas for the ceramic layer. Better correction work means a more uniform and reflective finish once coated.

Step 4: Isopropyl Alcohol Wipe Down

Even after polishing, tiny residues like polishing oils or waxes may linger on the surface, substances that severely interfere with bonding. We perform an isopropyl alcohol wipe-down, wiping every inch methodically with a solution designed to remove all trace oils and contaminants left behind by previous steps. This final cleanse ensures your newly polished paint is chemically clean and ready for coating application.

At M&B Paint Correction and Auto Reconditioning, we rely on this detailed prep checklist because it significantly enhances both the durability and appearance of ceramic coatings. Skipping or rushing through these stages often results in a patchy finish or premature coating failure.

Performance and Longevity Advantages

Paint correction is not just a cosmetic step but a foundational one that directly influences ceramic coating durability. When the surface is properly prepped and free of haze and oxidation, it creates an ideal canvas where ceramic coating can bond effectively and last longer.

Meticulous paint correction can extend the lifespan of your ceramic coating by up to 50%. Industry studies confirm that untreated or poorly prepared paint surfaces cause early coating failure, requiring premature reapplications. When we invest time in correcting paint, we're laying down a protective barrier that stays robust against environmental wear and tear over a longer period.

Superior Hydrophobic Performance

Beyond lasting longer, a corrected paint surface significantly boosts ceramic coating performance. Imagine trying to pour water onto a dusty window; it sticks and spreads unevenly. The same concept applies to your car's finish.

When the surface is polished and smooth after correction, ceramic coating can express its full hydrophobic properties. This means water beads roll right off, carrying dirt and grime instead of allowing buildup or stains.

Our clients notice how effortless it becomes to clean their cars after treatment. Mud and road salts simply don't adhere like before. Without paint correction, microscopic imperfections scatter water and contaminants unevenly, diminishing this critical protective feature.

Impact on Visual Quality and Resale Value

The transformation after paint correction is genuinely remarkable. When we carefully remove surface haze and oxidation, we're stripping away years of wear that cloud the true character of your vehicle's paint. This restoration sharpens colors so they appear deeper and more vibrant, almost as if the paint breathes anew.

The magic lies in how this refined surface interacts with the ceramic coating applied afterward. Ceramic coatings bond chemically to corrected paintwork, sealing in that freshly revealed gloss. Instead of a dull, muted finish hiding beneath layers of imperfections, you experience an almost mirror-like shine that reflects light with dazzling clarity.

Higher Resale Value Through Proper Maintenance

Better finish quality directly correlates with higher resale value and long-term preservation of your investment. When buyers appraise vehicles, they notice immediately whether paintwork has been maintained or cared for professionally.

Research indicates cars boasting pristine exteriors supported by paint correction and ceramic protection can sell for up to 15% more than comparable models with visible defects or fading. It's not merely about looks; it speaks volumes about how well the vehicle has been maintained overall.

We've observed clients gain confidence knowing their cars stand out in crowded marketplaces, whether at dealer lots or private sales. A flawless finish suggests no shortcuts were taken, and this reassurance often translates into quicker sales and better offers.

Making Your Final Decision

Choosing whether to undergo paint correction before applying ceramic coating isn't just a matter of preference; it's a decision that significantly affects the longevity and appearance of your vehicle's finish. When we assess this at M&B Paint Correction and Auto Reconditioning, we start by examining the vehicle's age and paint condition.

A newer car with minimal defects might need only light polishing or none at all before coating, while older vehicles often benefit greatly from full correction.

The reason is simple: ceramic coatings seal in what's already there. If your paint has surface haze or oxidation, these imperfections won't disappear under the coating; they'll simply be locked beneath a clear protective layer. Over time, those defects can become more noticeable or even degrade coating effectiveness.

Balancing Investment and Results

From our extensive experience working on everything from classic cars to daily drivers at our Isanti location, we firmly believe in addressing paint imperfections first. This layered approach ensures ceramic coating performs at its best, offering superior gloss, hydrophobic properties, and long-lasting protection.

We always advise our customers that investing in professional paint correction before coating leads to a far better return on investment through preserved value and enhanced aesthetics.

If you're weighing your options, our team invites you to schedule a consultation via our website. We provide thorough assessments tailored specifically to your vehicle's condition and usage patterns. Understanding exactly what your car needs allows us to recommend a treatment plan that balances your goals and timeline without sacrificing finish quality or longevity.

Frequently Asked Questions

Can ceramic coating hide imperfections without paint correction?

No, ceramic coating cannot hide imperfections. Ceramic coatings are transparent protective layers that bond to your paint's existing condition. They seal in whatever surface condition exists, meaning surface haze and oxidation will remain visible underneath. In fact, ceramic coatings can sometimes make imperfections more noticeable by adding a glossy layer that reflects light differently. Paint correction must be completed first to remove these defects and create the smooth surface needed for optimal coating performance.

Is paint correction necessary for new cars?

Even new cars often benefit from paint correction. Dealership handling, transport, and washing can introduce surface haze and light imperfections before you take delivery. Many new vehicles arrive with less-than-perfect paint due to these factors. However, new cars typically require only light correction compared to older vehicles, making the process quicker while still ensuring your ceramic coating bonds to a flawless surface.

How much does paint correction cost before ceramic coating?

The investment in paint correction varies based on vehicle size, paint condition, and the level of correction needed. At M&B Paint Correction and Auto Reconditioning, we offer comprehensive service packages that combine paint correction with ceramic coating application. We recommend scheduling a consultation for a detailed assessment and customized quote based on your vehicle's specific needs and your protection goals.

Will paint correction remove all imperfections from my car?

Paint correction can remove or significantly reduce most light to moderate surface haze and oxidation that haven't penetrated through the clear coat. The process focuses on restoring clarity and removing surface-level defects through careful compounding and polishing. During our assessment, we identify which imperfections can be corrected and which may need alternative solutions to ensure you have realistic expectations about final results. The goal is to create the smoothest possible surface for ceramic coating application.